Warehouse/material flow planning

Read more

Evaluation criteria

1. Article structure

-

-

Number of articles

-

Physical data (dimensions, weight, packaging, etc.)

-

ABC structure (withdrawal volume and access frequency)

-

2. Order types (node orders, direct orders, rush orders, etc.)

-

-

Order sizes

-

Order instructions (special texts)

-

Quantity of orders per time unit

-

Distribution across shipping units (pick, pack, O-pallet)

-

3. Throughput (Demand)

-

-

Fluctuation range at daily and monthly level

-

Marginal utilisation rates

-

Flexibility requirements

-

Response time (between order entry and order processing)

-

4. Picking quality

-

-

Customer requirements

-

System-related error probabilities

-

Possible quality assurance measures

-

5.Investment volume

-

-

Cost-benefit analysis

-

Specificity of the investments

-

Contract periods

-

6. Technical feasibility

-

-

Technical requirements

-

Structural conditions

-

Implementation period

-

Process simulation

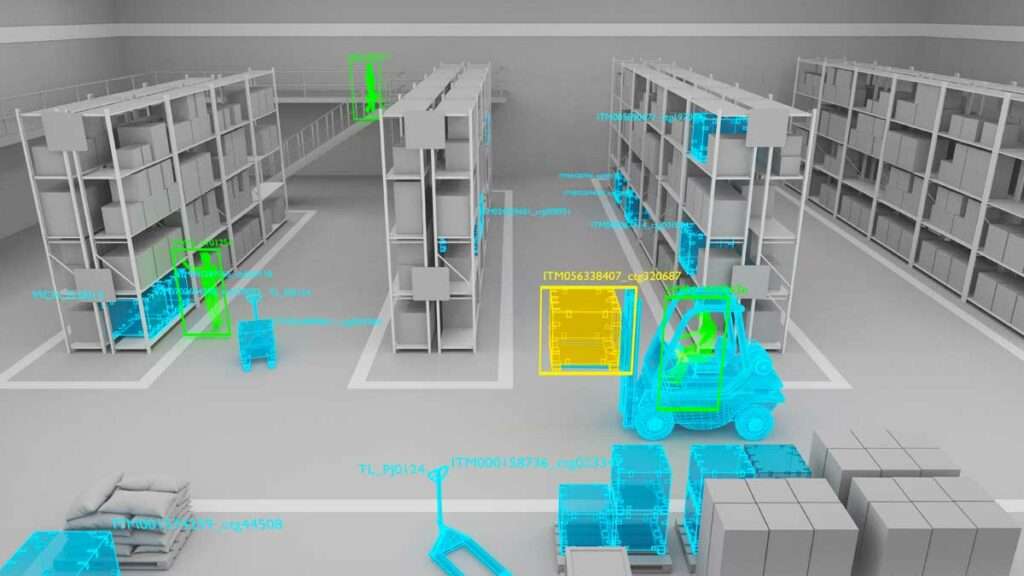

As the complexity of logistical processes increases, so do the demands placed on planning and strategy projects. Simulation offers the opportunity to check decisions risk-free and to plan processes on a secure basis, so that investments can be secured and considerable savings can be achieved in the realisation and operational phases.

Simulation techniques supports your planning and creates transparency. It maps the planned system on the computer and tests its dynamic behaviour on the basis of the stored flow data.

The many possible applications in logistics include, for instance, the simulation of complex warehouse and picking systems, the simulation of personnel deployment and mobility concepts and the creation of test environments for warehouse management software.

Read more

The basic intention when creating a new plant or modifying an existing system is to increase the profitability of a company.

The specific goals of a simulation study could, for example, be:

-

Increase in the machine utilisation

-

Reduction in staff requirement

-

Reducing storage space requirements

-

Increasing throughput

-

Shorter lead times

-

Evaluation of layout alternatives

-

Determination of the number of vehicles required in a driverless transport system

-

Determination of the buffer sizes required

-

Optimisation of control strategies

Essentially, a simulation can be useful to you in three project phases:

-

during the planning phase, when testing alternatives or scenarios

-

during the implementation phase to reach target values,

-

during the operating phase to further optimise the key performance indicators.

Layout design

The objective of logistics projects is often the optimisation of the logistics structure by improving the logistical process planning for all affected functional areas such as incoming goods, warehouse, order picking or dispatch area. In this context, cost-saving potentials or differentiation advantages result from a layout design of the logistics that is appropriate to the material flow. In order to tap potentials for shortening planning times, increasing planning quality or increasing planning effectiveness in the planning of logistics facilities and processes, digital methods of visualisation must be used consistently.

A comprehensive layout design often requires not only the detailed recording of all building and equipment details, but also the organisational and informational mediation between different planning instances. 3D layouts and multimedia representations of machines, plants and processes have meanwhile proven to be highly effective working tools in the communication between planners, designers and operators.

Project management

Of course, we are also looking forward to help you with the organisational implementation of your planning project. From the initial problem analysis, through target formulation and alternative evaluations, right up to completion, we will look after your logistics project.

Read more

We consider efficient project management to be:

-

The clear recording of all activities and their sequence. Complete presentation of the project process.

-

Exact scheduling including determination of time-critical points and the calculation of time reserves (network plan).

-

Integration of cost and financial management.

-

Preparation of documents for project preparation and project control. Immediate reaction on deviations from the plan.

-

Bundling of all relevant project information into a single project information system.

-

Integrative handling of all phases of the project (preparation, planning, realisation and control).